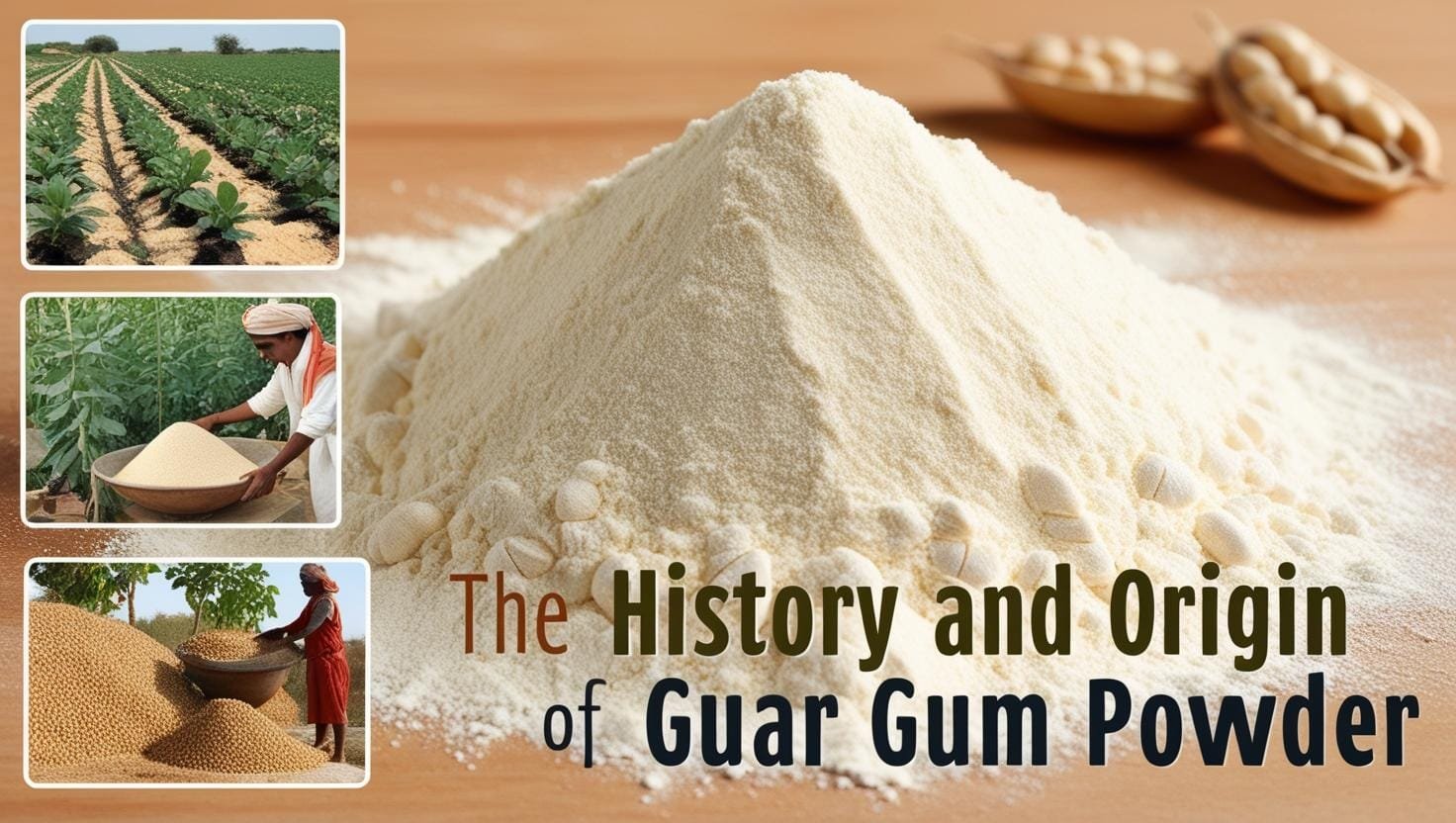

Guar gum is a natural polymer obtained from the seeds of the guar plant. It has gained immense popularity across various industries due to its incredible ability to thicken and stabilize formulations. In this blog, we’ll dive deeper into the concept of guar gum viscosity, a property that influences how guar gum interacts with different systems and applications. We will explore its applications in food and non-food industries, and discuss why it is a vital property for manufacturers.

What Is Guar Gum Viscosity?

Viscosity, in simple terms, is the measure of a liquid’s resistance to flow. Think of how honey flows slower than water – honey has higher viscosity. Similarly, guar gum viscosity refers to how the substance thickens solutions and creates a gel-like consistency when dissolved in water. This property of guar gum stems from its molecular structure, which is rich in galactomannan – a polysaccharide that traps water molecules. By doing so, guar gum forms a viscous solution that finds applications in numerous industries.

The Science Behind Guar Gum Viscosity:

When guar gum is added to water, it undergoes hydration, rapidly swelling to form a gel. Several factors affect guar gum viscosity, including:

1. Concentration: The more guar gum you add to water, the higher the viscosity of the solution.

2.Temperature: Higher temperatures can reduce viscosity, while lower temperatures promote gel formation.

3. pH Levels: Guar gum shows maximum viscosity in neutral to slightly acidic conditions.

4. Shear Rate: Guar gum exhibits shear-thinning behavior, meaning its viscosity decreases when stirred or subjected to stress.

These characteristics make guar gum viscosity highly adaptable and functional in different applications.

Applications of Guar Gum Viscosity in the Food Industry:

1. Enhancing Texture and Consistency:

One of the primary uses of guar gum in the food industry is as a thickening agent. Whether it’s sauces, soups, or ice creams, guar gum viscosity helps create smooth and uniform textures. For instance:

-> In low-fat dairy products, guar gum replicates the creaminess of full-fat versions.

-> In gravies and sauces, it prevents separation and ensures a consistent pour.

2. Stabilizing Emulsions:

Foods like salad dressings and mayonnaise rely on emulsifiers to keep oil and water mixed together. The high guar gum viscosity ensures that these mixtures stay stable, enhancing product shelf life and quality.

3. Improving Gluten-Free Products:

For individuals with gluten intolerance, baking without gluten can be challenging. Guar gum acts as a binding agent, improving dough elasticity and texture in gluten-free breads, cakes, and pastries. Guar gum viscosity ensures that these products maintain their structure and don’t crumble easily.

4. Preventing Ice Crystallization in Frozen Foods:

In frozen desserts like ice creams and sorbets, guar gum prevents the formation of ice crystals. This ensures that the texture remains smooth and creamy, even during long storage periods.

5. Enhancing Shelf Life:

The thickening and stabilizing properties of guar gum viscosity help extend the shelf life of various food products by preventing ingredient separation and degradation.

Applications of Guar Gum Viscosity in Non-Food Industries:

1. Oil and Gas Drilling:

One of the largest non-food applications of guar gum is in oil and gas drilling. Guar gum viscosity plays a critical role in creating drilling fluids that:

-> Stabilize the borehole during drilling.

-> Carry drill cuttings to the surface.

-> Control fluid loss in high-pressure environments.

Guar gum’s ability to hold up extreme conditions makes it an essential component in hydraulic fracturing operations.

2. Textile Industry:

In textile manufacturing, guar gum is used as a thickener for dye pastes. The high viscosity ensures uniform application of dyes on fabrics, reducing waste and improving color vibrancy.

3. Paper Industry:

The paper industry benefits from guar gum’s ability to enhance sheet formation and bonding. Its viscosity improves water retention, leading to stronger, smoother, and more durable paper products.

4. Cosmetics and Personal Care:

Guar gum is a common ingredient in shampoos, lotions, and creams. Its viscosity enhances product thickness, making it easier to apply while improving the sensory experience for consumers.

5. Mining and Explosives:

In the mining industry, guar gum viscosity is used to create gels that stabilize blasting agents. It is also used as a depressant in froth flotation processes to improve mineral separation efficiency.

Factors Affecting Guar Gum Viscosity:

Understanding the factors that influence guar gum viscosity allows manufacturers to optimize its use:

1. Particle Size: Finer guar gum particles dissolve faster and produce higher viscosity.

2. Hydration Time: Longer hydration allows guar gum to reach its full viscosity potential.

3. Additives: Salts and other chemicals can modify guar gum’s viscosity.

4. Storage Conditions: Extreme temperatures and humidity can affect guar gum’s performance over time.

The Benefits of Guar Gum Viscosity:

1. Versatility Across Industries:

Guar gum viscosity is adaptable, making it suitable for a wide range of products, from food to industrial applications.

2. Cost-Effectiveness:

Guar gum is a highly efficient thickening agent. Even small amounts can achieve the desired viscosity, making it a cost-effective choice for large-scale manufacturing.

3. Eco-Friendly:

As a natural and biodegradable polymer, guar gum is an environmentally friendly alternative to synthetic additives.

4. Improved Product Quality:

The ability to control guar gum viscosity ensures consistency, stability, and superior product performance.

Guar Gum Viscosity – Challenges and Solutions:

Despite its benefits, manufacturers may face challenges when working with guar gum viscosity:

1. Temperature Sensitivity: Guar gum may lose viscosity at high temperatures. Using stabilizers or blending it with other gums can mitigate this issue.

2. Incompatibility with Certain Ingredients: Some salts or chemicals can reduce guar gum’s viscosity. Testing formulations beforehand helps ensure compatibility.

3. Shear Sensitivity: Excessive stirring or mechanical stress can lower guar gum viscosity. Controlled processing conditions can prevent this.

By understanding these challenges, industries can maximize the potential of guar gum in their applications.

Why Manufacturers Rely on Guar Gum Viscosity?

Manufacturers value guar gum viscosity for several reasons:

1. It enhances the appearance, texture, and stability of products.

2. It reduces production costs by improving efficiency.

3. It meets consumer demands for clean-label, natural ingredients.

Future Trends in Guar Gum Viscosity:

As industries move toward sustainable and eco-friendly solutions, the demand for guar gum continues to rise. Innovations in processing technology and blending techniques are expected to further enhance guar gum viscosity, making it an even more versatile ingredient.

For example:

1. The food industry is exploring new uses for guar gum in plant-based products.

2. The oil and gas sector is developing advanced formulations to improve drilling fluid performance.

3. The cosmetics industry is leveraging guar gum’s viscosity to create biodegradable, high-performance skincare products.

Conclusion:

Guar gum viscosity is an essential property that drives innovation across a wide range of industries. Whether it’s enhancing the texture of ice cream, stabilizing oil drilling fluids, or improving the quality of paper, guar gum’s versatility makes it a valuable ingredient. By understanding how guar gum viscosity works and leveraging its potential, manufacturers can create high-quality, sustainable, and cost-effective products. The role of guar gum in food and non-food industries will continue to expand, as consumer demand for natural and clean-label ingredients which can offer endless possibilities for innovation.

FAQs:

1. What is Guar Gum Viscosity?

Guar Gum Viscosity refers to its ability to thicken or stabilize liquids and mixtures.

2. Why is Guar Gum used in the food industry?

Guar Gum is used to improve the texture, thickness, and stability of food products.

3. How does Guar Gum help in dairy products?

Guar Gum in dairy helps thicken yogurt, ice cream, and milk-based products, giving them a smooth texture.

4. Is Guar Gum used in non-food industries?

Yes, Guar Gum is used in oil drilling, cosmetics, paper manufacturing, etc. for its binding and thickening properties.

5. How does Guar Gum Viscosity impact food quality?

It ensures consistent thickness, improves shelf life, and enhances the overall quality of food.

6. Can Guar Gum be used in beverages?

Yes, Guar Gum helps stabilize and thicken beverages like juices and shakes.

7. Why is Guar Gum in dairy important?

Guar Gum in dairy ensures creamy textures and prevents the separation of liquids.

8. How is Guar Gum used in oil drilling?

Guar Gum helps control the flow and stability of drilling fluids, making the process smoother.

9. Are there benefits of Guar Gum in cosmetics?

Yes, Guar Gum improves the texture and consistency of creams, lotions, and shampoos.

10. Is Guar Gum environmentally friendly?

Yes, Guar Gum is natural, biodegradable, and safe for various applications.