If you’re new to the world of industrial raw materials, you’ve likely heard of guar gum. Known for its thickening and stabilizing properties, guar gum plays a major role across several industries. In this blog, we’ll walk you through the basics of Guar Gum Industrial Uses in simple terms, so that even first-time buyers can make informed decisions.

Whether you’re sourcing for oil drilling, textile manufacturing, paper production, or food processing, understanding the Guar Gum Industrial Uses can help you pick the right grade and form for your needs.

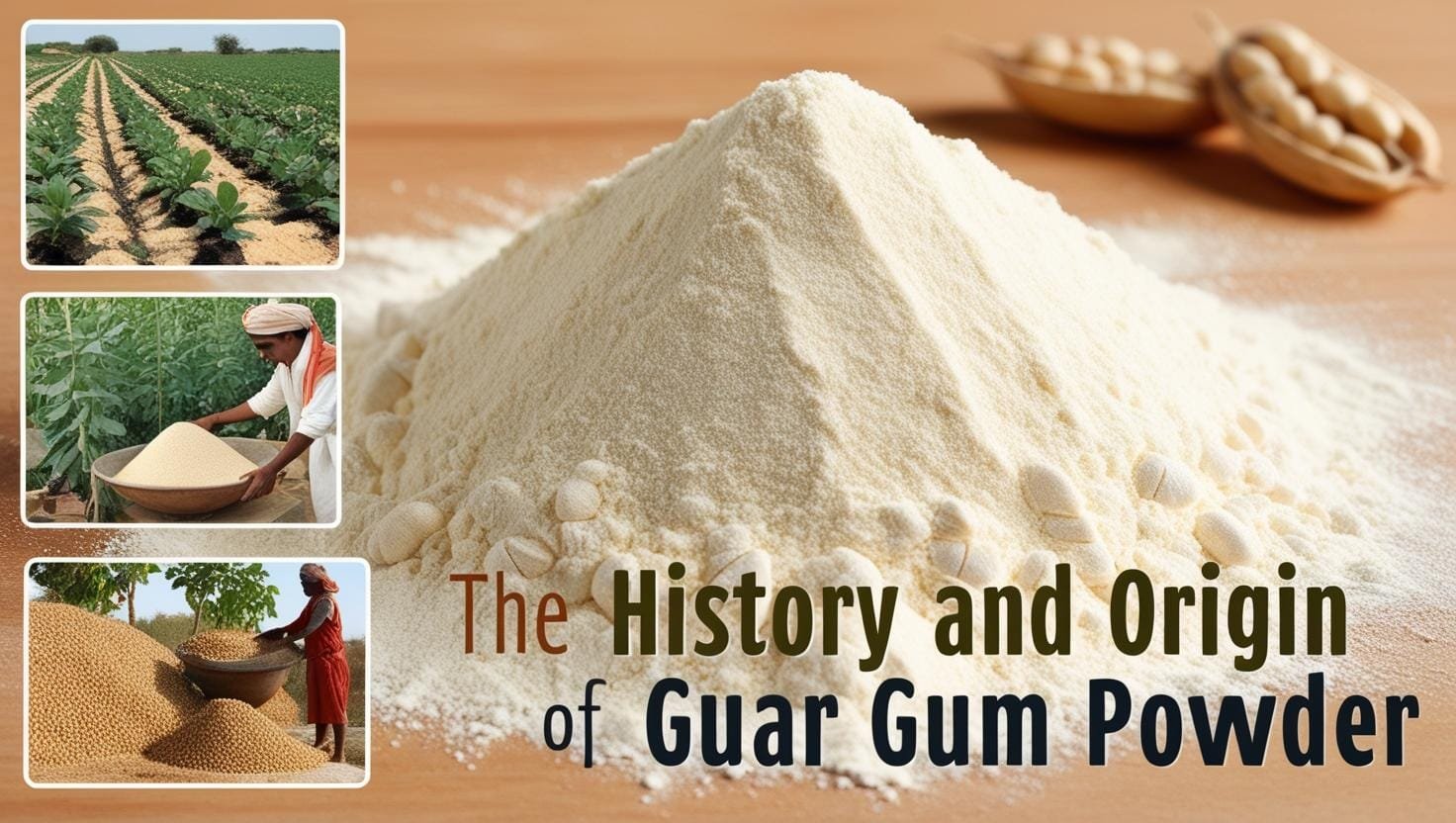

What is Guar Gum?

Guar gum is a natural powder derived from the guar bean plant (Cyamopsis tetragonoloba). It’s a type of natural thickener used to increase viscosity and improve the texture of liquids and pastes. It is commonly available in different mesh sizes and viscosities, depending on its end use.

You may come across two major types:

1. Food grade guar gum: Used in food processing.

2. Industrial grade guar gum: Used in non-food applications like textiles, paper, oil drilling, and mining.

Why Is Guar Gum So Popular in Industries?

The wide guar gum applications across different sectors are due to its:

1. High water-binding capacity

2. Natural origin and non-toxic nature

3. Cost-effectiveness compared to synthetic alternatives

4. Ability to work in both cold and hot water

5. Compatibility with other ingredients and chemicals

Let’s now explore the most common Guar Gum Industrial Uses that new buyers should know.

1. OIL AND GAS INDUSTRY

One of the major Guar Gum Industrial Uses is in oil drilling. Guar gum powder is used to prepare drilling fluids or fracking gels that carry proppants like sand into oil wells. It acts as a thickener and helps suspend solid particles in the drilling mud.

This makes guar gum an essential additive in hydraulic fracturing operations, especially in countries like the USA and Canada.

2. TEXTILE INDUSTRY

Another key entry in Guar Gum Industrial Uses is textile printing and sizing. Guar gum works as a thickening agent for dye pastes. It helps dyes stick properly to fabric during printing or screen printing. It is also used in warp sizing to protect yarn from breakage during weaving.

New buyers in textile manufacturing should look for high-viscosity guar gum with good film-forming properties.

3. PAPER INDUSTRY

In the paper industry, Guar Gum Industrial Uses include surface sizing and coating. It improves sheet formation, gives a smooth finish, and enhances print quality. Guar gum also acts as a binder for coatings and reduces the use of more expensive chemicals.

It helps in controlling the absorption and spreading of ink, especially in high-quality paper production.

4. MINING AND EXPLOSIVES INDUSTRY

In mining and explosives, Guar Gum Industrial Uses focus on dust control, ore flotation, and as a binder in blasting explosives. It helps stabilize and thicken mixtures used in explosive gels, making them safer and more effective.

Guar gum increases water retention in the blasting slurry, helping maintain uniform consistency.

5. CONSTRUCTION INDUSTRY

Guar gum is also used in construction chemicals, including cement-based adhesives and grouts. It improves bonding, spreadability, and water retention, making it a key part of dry mix formulations.

While not as well-known, this is a growing segment of Guar Gum Industrial Uses, especially in eco-friendly construction materials.

6. COSMETICS AND PERSONAL CARE INDUSTRY

Yes, there are Guar Gum Industrial Uses even in non-edible personal care products. Guar gum acts as a thickener and stabilizer in shampoos, lotions, and creams. It gives a smooth feel, improves shelf life, and enhances texture.

Though food-grade is not required here, a refined industrial grade with low impurities is preferred.

7. WATER TREATMENT AND FLOCCULATION INDUSTRY

In water treatment plants, Guar Gum acts as a flocculant. It helps bind small particles into larger ones, which then settle faster. This makes the purification process more efficient.

It’s particularly useful in wastewater treatment for removing sludge and impurities from large-scale industrial discharge.

8. DETERGENT AND CLEANING PRODUCTS INDUSTRY

Guar gum powder is added to detergents as a thickener and stabilizer. It helps in suspending insoluble particles and improves shelf life by stabilizing the mix.

These Guar Gum Industrial Uses are common in the production of liquid soaps, dishwashing gels, and even car cleaning fluids.

9. INCENSE STICKS AND MATCHSTICKS INDUSTRY

An interesting but lesser-known area of Guar Gum Industrial Uses is in agarbatti (incense sticks) and matchstick production. It acts as a binding agent, helping powders stick to the bamboo stick and burn evenly.

It ensures proper adhesion without affecting burn time or fragrance.

10. AGRICULTURE AND HORTICULTURE INDUSTRY

In agriculture, guar gum helps in seed coating and fertilizer binding. It acts as a soil stabilizer and improves water retention. Some companies use guar gum in pesticide sprays to help active ingredients stick better to plant surfaces.

These Guar Gum Industrial Uses are often overlooked but are very effective in enhancing productivity.

Grades of Industrial Guar Gum:

When buying guar gum for industrial purposes, you should know about the following grades:

1. Fast Hydration Guar Gum (FHG) – Common in oil drilling

2. High Viscosity Guar Gum – Used in textiles and paper

3. Medium Viscosity Guar Gum – Used in mining, detergents, and cosmetics

Be sure to ask for a COA (Certificate of Analysis) and check for mesh size, pH value, and viscosity levels before buying.

How to Choose the Right Supplier:

As a new buyer, one should ensure:

-> The supplier has FSSAI or ISO certifications if dealing in food/non-food grades.

-> The product is packed properly to avoid moisture absorption.

-> Check whether the guar gum is refined or derivative-based, based on your application.

-> Choose exporters with a good track record and global reach, especially if you’re sourcing in bulk.

What to Check when Buying Guar Gum:

As a new buyer looking at Industrial Uses of guar gum, keep these tips in mind:

1. Ask for viscosity data and mesh sizes

2. Choose grade based on your industry (Food Grade, Industrial Grade, Fast Hydration, Partially Hydrolyzed)

3. Confirm supplier offers ISO / FSSAI or export certifications

4. Always request a COA (Certificate of Analysis) or Technical Data Sheet.

Storage and Handling Tips:

A) Store in a cool, dry place away from moisture.

B) Keep bags sealed properly after opening.

C) Avoid exposure to direct sunlight.

D) Improper storage can lead to clumping or fungal growth, especially in humid regions.

Conclusion: Why Guar Gum Is a Reliable Industrial Ingredient:

As seen, Guar Gum Industrial Uses span across oil, textile, mining, cosmetics, and even agriculture. For new buyers, the key is to identify the end application and select the correct grade and mesh size.

Guar gum stands out because it is:

-> Natural and biodegradable

-> Versatile across industries

-> Cost-effective compared to synthetic thickeners

-> Easily available in bulk

Whether you are a manufacturer, formulator, or distributor, understanding the Guar Gum Industrial Uses will help in sourcing the right quality at the best price.

FAQs:

1. What are the main Guar Gum industrial uses?

Guar Gum is widely used in industries like oil drilling, textiles, paper, cosmetics, and food processing for its thickening and stabilizing properties.

2. How does particle size affect Guar Gum industrial uses?

The finer the particle size, the better the hydration rate and performance in industrial applications.

3. How does Guar Gum benefit the textile industry?

Guar Gum is used as a sizing and printing thickener in textile manufacturing, ensuring smooth processing.

4. Are there eco-friendly advantages of Guar Gum industrial uses?

Yes, Guar Gum is biodegradable and plant-based, making it a sustainable alternative to synthetic chemicals.

5. Why should new buyers understand Guar Gum industrial uses before purchasing?

Understanding Guar Gum industrial uses helps buyers choose the right grade and application, ensuring better performance and cost-efficiency.

6. Are there different grades for Guar Gum industrial uses?

Yes, Guar Gum is available in food, technical, and industrial grades depending on the application requirements.

7. Can Guar Gum reduce production costs?

Yes, its efficiency as a thickener and stabilizer often reduces the need for multiple additives, saving costs.

8. What makes Guar Gum ideal for hydraulic fracturing?

One of the major use of Guar Gum in hydraulic fracturing is that it helps to create viscous gels for efficient sand transport.

9. Is Guar Gum regulated by any standards?

Yes, depending on the region and industry, its use may follow guidelines such as ISO, ASTM, or local chemical compliance standards.

10. What safety measures are important during the industrial use of Guar Gum?

Proper storage in cool, dry conditions is essential to maintain Guar Gum’s functionality in industrial uses.