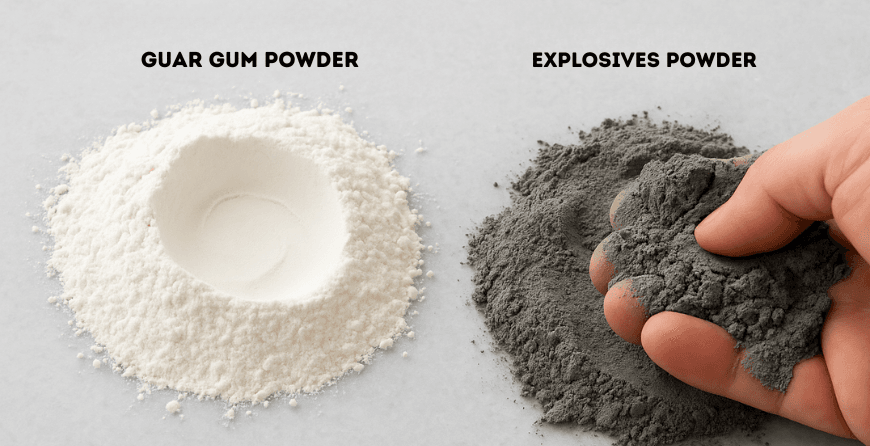

Guar gum might not be the first thing that comes to mind when you think about explosives, but it’s a crucial ingredient in this industry. Guar Gum in Explosives is better known for its thickening and stabilizing properties, it has a surprising role in making explosives more efficient and safer to handle. In this blog, we’ll explore how guar gum is used in explosives manufacturing, its benefits, and other industrial uses.

Overview of Guar Gum:

Guar gum is a natural thickener made from guar beans. It is widely used in food, cosmetics, and pharmaceutical industries due to its ability to thicken and stabilize products. But its applications go beyond these everyday uses. One of the lesser-known yet important applications of guar gum is in the explosives industry.

Guar Gum in Explosives Manufacturing:

In the explosives industry, guar gum is valued for its ability to act as a thickener and stabilizer. When mixed with other components, guar gum helps to create a uniform and stable mixture. This stability is crucial for ensuring the safety and effectiveness of explosives. Here’s how guar gum contributes to the process:

A. Thickening Agent: Guar gum thickens the explosive mixture, making it easier to handle and apply. This is particularly important in the production of slurry explosives, which are liquid or semi-liquid formulations. The thickening property of guar gum ensures that the mixture maintains the right consistency.

B. Stabilizing Agent: Stability is key in explosives manufacturing. Guar gum helps to keep the mixture stable by preventing the separation of ingredients. This ensures that the explosive remains effective over time and reduces the risk of accidental detonation during handling and transportation.

C. Water Retention: In many explosive formulations, water is a critical component. Guar gum has excellent water retention properties, which help to keep the mixture hydrated. This is particularly useful in hot and dry conditions where water might evaporate quickly.

D. Cost-Effective: Guar gum in explosives is relatively inexpensive compared to synthetic alternatives. Its natural origin and ease of production make it a cost-effective choice for explosives manufacturers.

Benefits of Using Guar Gum in Explosives:

The use of guar gum in explosives offers several benefits:

1. Enhanced Safety: By providing stability to explosive mixtures, guar gum reduces the risk of accidental detonations, making the handling and transportation of explosives safer.

2. Improved Efficiency: The thickening and stabilizing properties of guar gum ensure that the explosive mixture is uniform, which improves its performance and effectiveness.

3. Environmental Friendliness: Being a natural product, guar gum is more environmentally friendly compared to synthetic chemicals used in explosives.

4. Easy to Handle: Guar gum makes explosive mixtures thicker, so they are less likely to spill or leak. This makes the explosives easier and safer to transport and use.

5. Consistent Performance: Explosives mixed with guar gum perform more consistently because the ingredients stay evenly distributed. This means the explosive works the same way each time it’s used.

6. Less Dust: Guar gum helps reduce the amount of dust produced when handling dry explosive powders. Less dust means a safer working environment and less risk of inhaling harmful particles.

7. Better Storage: Guar gum helps keep explosives stable over time, so they last longer in storage without losing effectiveness. This is especially important for companies that need to store explosives for long periods.

Drawbacks or Limitations to using Guar Gum in Explosives:

While guar gum is beneficial for use in explosives, there are some potential drawbacks and limitations to consider:

- Dosage Sensitivity: Guar gum must be used in the correct dosage to achieve the desired properties. Incorrect dosages can negatively affect the performance of explosives or drilling fluids.

- Chemical Compatibility: It’s important to ensure compatibility with other chemicals and materials. Incompatibility can lead to reduced effectiveness or even failure of the explosive material.

- Cost and Availability: The cost and availability of guar gum can fluctuate due to market demand, especially since India is a major producer. This can impact the cost-effectiveness of using guar gum in explosives.

- Environmental Impact: The production of guar gum involves significant water usage, which can be a concern in arid regions where water is scarce.

- Storage and Handling: Guar gum requires careful storage and handling to maintain its properties. Exposure to moisture, for example, can trigger premature swelling and spoilage.

- Performance in Wet Conditions: While guar gum is used for water resistance, it may not perform as well in extremely wet conditions compared to other materials.

These limitations highlight the need for careful consideration and management when using guar gum in explosive formulations to ensure safety and effectiveness.

Other Guar Gum Applications:

Apart from its role in the explosives industry, guar gum has numerous other applications. Its versatility makes it a valuable ingredient in various sectors:

1. Food Industry: Guar gum is commonly used as a thickener and stabilizer in products like ice cream, sauces, and salad dressings. It helps to improve texture and shelf life.

2. Cosmetics: In the cosmetics industry, guar gum is used in lotions, creams, and shampoos to enhance texture and stability.

3. Pharmaceuticals: Guar gum is used in the pharmaceutical industry as a binder and disintegrant in tablets. It also helps in the controlled release of drugs.

4. Oil and Gas: Guar gum is used in hydraulic fracturing (fracking) fluids to thicken the fluid, which helps to carry proppants into the fractures to keep them open.

5. Textiles: In the textile industry, guar gum is used as a sizing agent to strengthen fibers during the weaving process.

6. Paper Industry: Guar gum is used in the paper industry to improve sheet formation and enhance the physical properties of paper.

Industrial Uses of Guar Gum:

The industrial uses of guar gum are vast, showcasing its importance beyond food and cosmetics. Its ability to thicken, stabilize, and retain water makes it an invaluable ingredient in various processes. In the explosives industry, these properties translate to improved safety, efficiency, and cost-effectiveness.

Conclusion:

Guar gum in explosives manufacturing is a prime example of how a natural product can play a crucial role in industrial applications. Its thickening and stabilizing properties ensure the safety and effectiveness of explosive mixtures, making it a vital component in the industry. Beyond explosives, guar gum’s versatility is evident in its wide range of applications, from food and cosmetics to oil and gas.

FAQs:

1. How is guar gum used in explosives?

It thickens and stabilizes the explosive mixtures.

2. Why is guar gum important in explosives manufacturing?

It makes explosives safer and more efficient to handle.

3. What are the benefits of using guar gum in explosives?

Enhanced safety, better stability, and cost-effectiveness.

4. Is guar gum used in all types of explosives?

It’s used in many types, especially in industrial blasting agents.

5. How does guar gum improve explosive safety?

It stabilizes the mixture, reducing the risk of accidental blast.

6. Where can i find high-quality Guar Gum for explosives manufacturing?

You an find Guar Gum for your explosives manufacturing from retailers or producers such as Durga Enterprises.

7. Why is guar gum better than synthetic alternatives?

It’s natural, cost-effective, and environmentally friendly.

8. What other properties does guar gum have?

Besides thickening, it has excellent water retention and stabilizing properties.

9. How does guar gum help in water retention?

It helps keep the explosive mixture hydrated, especially in dry conditions.

10. How does guar gum impact the longevity of explosives?

It helps extend the shelf life by preventing moisture absorption.

11. Does temperature affect guar gum in explosives?

Guar gum remains stable under various temperature conditions.